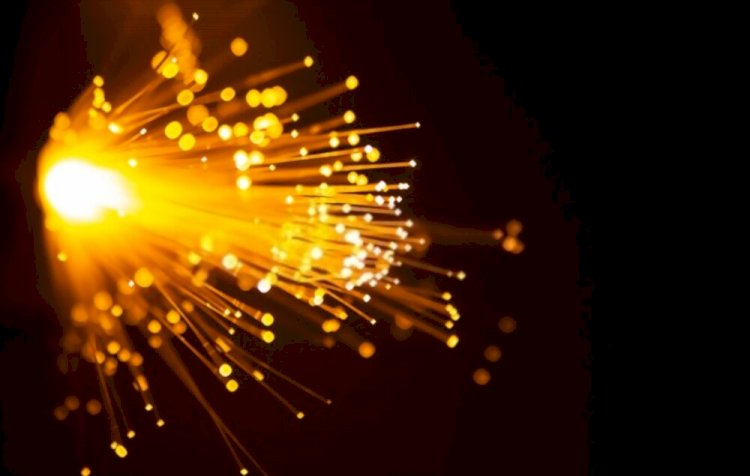

All You Need to Know About PMMA Optical Fiber

The polymer optical fiber is majorly used by automobile manufacturers and for industrial purposes because of its various advantages. The large core size, high flexibility, dependability, etc.

Polymethyl Methacrylate known as PMMA is used to manufacture optical fiber. In the PMMA optical fiber, the cladding material is made up of fluorinated polymer whereas, the core is made up of PMMA. This optical fiber is pellucid to light and looks similar to a nylon rope. The cladding of the polymer optical fiber ensures that the light travels inside the core and throughout its length.

Characteristics of PMMA Optical Fiber

- The refractive indices of 1.49 and 1.59 of PMMA are used to manufacture the core.

- There is a huge difference between the refractive indices of the core and the cladding.

- The numerical aperture of PMMA is significantly high

- PMMA optical fiber is highly flexible

Advantages of PMMA Optical Fiber

The polymer optical fiber is majorly used by automobile manufacturers and for industrial purposes because of its various advantages. The large core size, high flexibility, dependability, etc., are some of the major advantages that make it one of the most preferred optical fibers. One of the best parts about using this optical fiber is that the connectivity can be diagnosed easily by checking whether the light emits out from its end. Besides, one of the other advantages of using this optical fiber is that it is durable when compared to its counterparts available in the market. There are various other benefits of PMMA optical fiber. Some of them are as follows:

Durability: The durability of this optical fiber is impeccable as they work even in extreme climatic conditions. They work perfectly in salted and high humidity atmosphere. Besides this, they work from -40 degrees Celsius to +85 degrees Celsius. As it does not oxidize, you can expect a minimum life span of 20 years. One thing that you should keep in mind is that the core of this fiber should not come in direct contact with UV rays as it transparent and can turn yellow due to chemical changes.

Flexibility: The Polymethyl Methacrylate optical fiber is highly flexible when compared to glass fiber or traditional copper wires. The maximum bend radii of this optical fiber is approximately 20mm. When the wire bends more than the tolerant limit, then it can lead to transmission loss. Therefore, it is advisable to use multi-core POF in materials that have significant bending cycles.

Diameter: The outer diameter of the PMMA optical fiber is 1000 micrometer whereas, its core diameter is 980 micrometer. The diameter of this optical fiber is eight times larger when compared to the diameter of the glass fiber.

Insulation: Polymer optical fiber is made up of insulating materials, therefore, it becomes an ideal option to use in the flammable environment as it does not conduct electricity. Besides this, it is also prone to the EMI, i.e., electromagnetic interference, therefore, making it feasible for industrial use.

Easy to handle: The PMMA optical fiber is easy to handle as they are relatively easy to repair. If you are repairing the traditional copper wire, all you have to do is cut, twist and, join them together. If you want to remove the damaged section of this optical fiber then you will have to use either one of the two methods, i.e., fusion splicing or mechanical splicing.

To sum it up

If you are looking for PMMA optical fiber for industrial, medical, or automotive manufacturing use, there are numerous suppliers available in the market that can meet your requirements. Understanding the various qualities of such fiber becomes necessary before using it for various applications. So, search the web for a professional and experienced company that can help you with the perfect solution for your upcoming project.

Share

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

1