Vacuum Filters: A Key to Fast Filtration Technique

Vacuum filters are reliable and simple machines and hence, have gained wide acceptance in the food, chemical, and pharmaceutical companies.

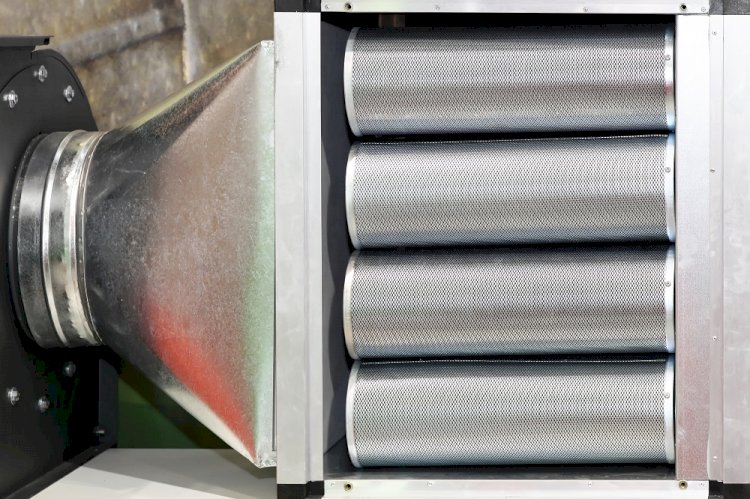

Vacuum filters are reliable and simple machines and hence, have gained wide acceptance in the food, chemical, and pharmaceutical companies. The job of vacuum filters is to capture dust particles before it damages the motor inside. Vacuum cleaners or exhaust filters are normally operated using suctions. The suction filtration and vacuum filtration is the fundamental method that is used for separating a solid-liquid mixture when the aim is to retain the solid, for example, crystallization. Vacuum filters use a method for separating solid products from a liquid. The filtrate pump removes the water that is filtered out of the concentrate. It works with the filter and vacuum pump in a circuit.

Industrial Vacuum Filters In Vacuum Pumps

The filtration process is enhanced either with the help of pressure or vacuum. The regulation and ultimate vacuum requirements are generally modest for the vacuum filters. If the vacuum filtration is at 100mbar then 90% of the atmospheric pressure would be accessible as the driving force for vacuum filters. A little impact is there on the process when the vacuum level is improved further. In some cases, the two-stage pumps with high pumping speed accelerating the filtration process.

Vacuum pump filters are designed to prevent dust particles from entering or exiting the vacuum pump and thus prevent from contaminating the vacuum pump system components. Vacuum exhaust filters are widely used on an oil-sealed rotary vane type of pumps. Besides this, a vacuum pump exhaust filter is also known as an oil mist eliminator.

Oil mist or oil vapor is generated by these pumps for a variety of reasons. This is caused due to the operation of the pumps at very low pressure. The vacuum pump generates oil mist with operating pressure above 1 torr or 1000 micron. Due to pumping against the leaky system, the oil mist is created. The process through which the vacuum gas passes through the complex paths atomizes the oil molecules.

Types Of Vacuum Filters

There are usually two types of vacuum filters: exhaust filters and intake filters.

Exhaust filters:

The exhaust filters also known as coalescing filters, trap the oil mist and usually store in the pump. Coalescing means the oil drains back into the pump after it has been condensed inside of the filter element.

Intake filters:

The intake vacuum filters are usually of high density and having a low porous type filter, the vacuum helps in removing dust particulates from the intake port of the vacuum pump.

Many times, multistage filtration is required. This filter system contains two or more stages. This filter system consists of layered filters which progressively removes particulates and oil mist. The first stage of the filter is the oil mist eliminator. The second phase of filtering consists of a disposable charcoal trap which removes volatile organic compound from the vacuum.

Advantages Of Using Vacuum Filters

- Performs continuous operation

- Easy control of operating the parameters

- Produces relatively clean filtrates by using a sedimentation basin or a cloudy port.

- Intensive soluble recovery or removal of contamination

Rough vacuum pumps are a significant phase of the vacuum system. For productive and safe operations, accurate filters and trap must be installed on both the inlet and outlet of the vacuum pump. This becomes more important as more solvents and other materials are being pumped. Using proper filters and traps and also maintaining these items can improve the life of the vacuum pump as well as minimize the dangerous emissions in the environment.

Share

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0