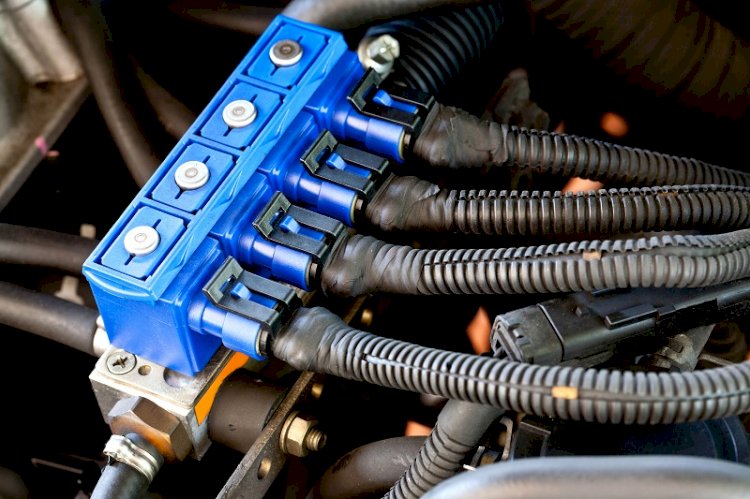

Fuel Injection System components

In order for the fuel injector parts being able to put under best utilization, fuel are should get transferred to the fuel injection system from the fuel tank.

In order for the fuel injector parts being able to put under best utilization, fuel are should get transferred to the fuel injection system from the fuel tank. This accounts for the role played by the low-pressure fuel system components. The low-pressure side of the fuel system consists of a number of components. These components include the fuel tank, one or more of the fuel supply pumps, and one or more of these fuel filters. Besides, there are a number of fuel systems that are seen to contain coolers as well as heaters. These help in better controlling of fuel temperature.

The Fuel Tank

The fuel tank is one of the chief components in the entire fuel injection system. It is a reservoir that holds the fuel supply and therefore helps in maintaining its temperature at a level that is below its flashpoint. The fuel tank also serves as an important means of dissipating heat from the fuel that is returned from the engine. This fuel injector part should possess the properties of corrosion-resistivity. The leak-proof to pressures should be maintained at 30 kPa. Usage of means to prevent excessive pressure accumulation with devices like a vent or a safety valve is mandatory too.

The fuel Supply Pump

The fuel supply pump is responsible for drawing fuel from the tank. The drawn fuels are then disposed of in a high-pressure pump. These electrically or mechanically driven fuel injector parts are characterized by the diversified functionalities. Most of these operations are controlled by a centralized engine. While an electrically driven fuel pump is used, the system allows the pump to be placed anywhere within even inside the fuel tank. Some of the fuel pumps may be incorporated into sub-components for facilitating different functionalities. For instance, the tandem pumps belong to those units that incorporate a fuel pump and a vacuum pump for the brake booster. There are fuel systems, which are based on a distributor type pump. These are seen to incorporate a mechanically driven supply pump and the high-pressure pump under the same system.

Fuel pumps are special types of fuel injector parts that are commonly sized to deliver more fuel in excess to that consumed by the engine at any particular operating system. This extra fuel flow thus consumed can serve a number of important functions. This may include providing for the extra fuel to help to cool injectors, pumps and other engine components, and maintaining a more constant temperature of the fuel in the entire fuel system. The excess fuel might also be heated by its contact with a hot engine. The components can be returned to the tank or fuel filter. This may be utilized to improve the low-temperature operability of a vehicle.

The Fuel Filter

In order to give access to trouble-free fuel injection through various fuels injector parts, the use of filter seems to be most cohesive option. The filtering of fuel helps in the reduction of damage and premature wear from contaminants. This is done by retaining very fine particles and water to prevent them from entering into the fuel injection system.

The fuel injection within a system of filtering is divided into dual stages. The two-stage filter system typically uses a primary Fuel injector parts on the inlet side of the fuel transfer pump and a secondary one on the outlet side. The primary part is required to remove larger particles. The secondary filter is used to bear with higher pressures. This also helps in the removal of smaller particles that may damage the engine components. One-stage systems remove larger and smaller particles in a single filter.

Share

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0